Applied standard

Load meets or exceeds the following standards: ASTM E4, ISO7500-1, EN 10002-2, BS1610, DIN 51221.

Strain measurement meets or exceeds the following standards: ASTM E83, ISO 9513, EN 3846 and EN 10002-4.

Safety: The single space Servo-Hydraulic UTM of Compact Type shall conform to all relevant European CE Health and Safety Directives EN 50081-1, 580081-1, 73/23/EEC, EN 61010-1

Tensile test at room temperature: DIN EN 10002-1, ISO 6892, ASTM A370, ASTM E 8

Tensile test on reinforced steel: ISO 10606, EN 10080

Compression test: DIN1048, ISO6784, ASTM C39, ISO4506

ASTM E143 Test Method for Shear Modulus at Room Temperature

ASTM F606-07 Tensile test for bolts

ASTM A185/A185M-07 Metals & Construction material

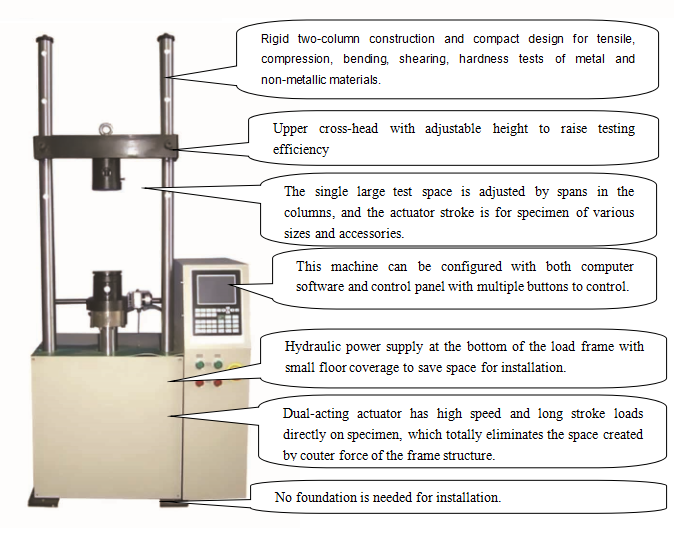

Load Frame Structure

HLC series Servo-Hydraulic UTM of Single Space adopts single testing space designed with single central hydraulic drive for loading on specimen directly to do the tests of tensile, compression, bending and shearing etc.. The space created by counter force frame structure is totally eliminated so that the testing results are more accurate and real. The single large test space fully considers operation convenience and safety that raise testing efficiency. Such a large test space also entitles the load frame to adapt a wide range of specimen sizes, grips, accessories, extensometers, furnace, environmental chambers etc.

|

Model

|

HLC-50

|

HLC-100

|

HLC-150

|

HLC-200

|

|

Load Capacity (KN)

|

50

|

100

|

150

|

200

|

|

Load Accuracy (%)

|

±0.5%/ ±1%

|

|

Actuator Stroke (mm)

|

200

|

|

Max. Test/Loading Speed (mm/min)

|

100

|

|

Max. Tensile Space (mm)

|

350

|

|

Max. Compression Space (mm)

|

635

|

|

Distance Between Columns (mm)

|

360

|

|

Tensile Jaw For Flat Specimen (mm)

|

0 - 21

|

0 - 27

|

|

Tensile Jaw For Round Specimen (mm)

|

4 - 20

|

9 - 26

|

|

× of Jaw (mm)

|

40×55

|

50×75

|

|

Bending Fixture Span (mm)

|

20 - 400

|

30 - 420

|

|

Length of Bending Roller (mm)

|

100

|

100

|

|

Diameter of Bending Roller (mm)

|

Φ20

|

Φ30

|

|

of Bending Supporter (mm)

|

90

|

100

|

|

Compression Platen (mm)

|

Ø100

|

|

Hydraulic Oil Requirement

|

ISO VG68# or VG46# hydraulic oil

|

|

Volume of Oil Tank (L)

|

13

|

|

Oil Pump Flow Rate (L/min)

|

2

|

|

Pressure of Hydraulic Power Pack (MPa)

|

21

|

|

Power Supply

|

3 phase, 380V/220V±10%, 50Hz/60Hz

|

|

Dimensions of Load Frame (mm)

|

750 × 510 × 1610

|

|

Weight (kg)

|

290

|

|

Shipping Dimension (mm)

|

1300×700×1700

|