Applied Standard

● Load meets or exceeds the following standards: ASTM E4, ISO7500-1, EN 10002-2, BS1610, DIN 51221.

● Strain measurement meets or exceeds the following standards: ASTM E83, ISO 9513, BS 3846, EN 10002-4.

● Safety: This machine shall conform to all relevant European CE Health and Safety Directives EN 50081-1, 580081-1, 73/23/EEC, EN 61010-1

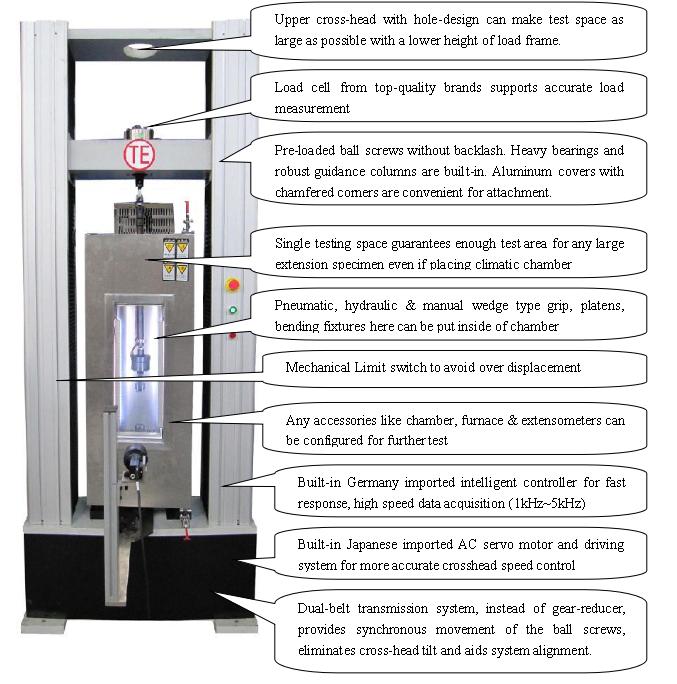

Load Frame

According to load capacity and test application, the load frames are available in single column, table and floor type to meet different test applications.

Single column machine is more suitable for bio-medical, textiles, plastic film industries where load testing requires a lower capacity. Dual-column table type is the main choice for rubber, plastic, composites and metal sectors where the specimen needs a wide test area and middle strength. Floor type is the optimal units for most demanding applications of metal, alloys, and fasteners, whose specimen needs a high capacity of size and strength.

The frames all take human factors into considerations in the design to ensure the safety, reduce operators’ fatigue and provide the highest flexibility. The extremely robust cross-head guidance is incorporated in all frame designs so as to provide the highest stiffness of lateral cross-heads.

With gap-less load frames, the testing system imports larger capacity servo motor, stable driving system and advanced control system and can complete the low cycle fatigue test like square and trapezoidal waveform under 0.5 Hz.

Superior Load Frame Design

Superior Load Frame Design

| Model |

WDW-S1/2/5S |

WDW-1/2/5/10/20S |

WDW-25/30S |

WDW-50/100S |

WDW-200/250/300S |

WDW-500/600S |

| Max. load (kN) |

1/2/5 |

1/2/5/10/20 |

25/30 |

50/100 |

200/250/300 |

500/600 |

| Load measuring range |

0.2%(1/500)~100%(1/1)FS |

| Load accuracy |

±0.5%/Class 0.5 (better than ASTM E4, ISO7500-1, EN 10002-2, BS1610, DIN 51221) |

| Deformation measuring range |

0.4%(1/250)~100%(1/1)FS |

| Deformation accuracy |

±0.5%/Class 0.5 (better than ASTM E83, ISO 9513, BS 3846, EN 10002-4) |

| Position resolution |

0.006μm |

| Position accuracy |

±0.01mm or 0.05% of displacement (whichever is greater) |

| Crosshead moving speed (mm/min) |

0.001-1000 |

0.0015-1500 |

0.001-1000 |

0.0005-500 |

| Crosshead moving speed accuracy |

±0.1% of set speed (zero or constant load) |

| Maximum speed at full load (mm/min) |

1000 |

1500 |

1000 |

500 |

| Maximum load at full speed (kN) |

1/2/5 |

1/2/5/10/20 |

25/30/50 |

50/100 |

200/250/300 |

500/600 |

| Vertical test space1 (mm) |

990 |

1300 |

1700 |

1500 |

| Total crosshead travel (mm) |

900 |

1200 |

1600 |

1400 |

| Column spacing (mm) |

/ |

420 |

500 |

570 |

590 |

650 |

| Max. tensile space2 (mm) |

700 |

750 |

550 |

| Max. compression space3 (mm) |

810 |

1200 |

1050 |

| Tensile jaw for round specimen(mm) |

/ 4 |

Φ4~Φ14 |

Φ4~Φ20 |

Φ8~Φ32 |

Φ12~Φ40 |

| Tensile jaw for flat specimen (mm) |

0~8 |

0~14 |

0~21 |

0~27 |

0~30 |

| x of jaw (mm) |

40 x 60 |

35x55 |

40x55 |

50x75 |

70x90 |

| Compression platen diameter (mm) |

Φ50 |

Φ100 |

| Bending fixture span(mm) |

/ 5 |

10-300 |

20-300 |

20-400 |

30-420 |

30-450 |

| Length x dia. of bending roller (mm) |

/ |

100xΦ10 |

100xΦ20 |

140xΦ30 |

| of bending supporter (mm) |

/ |

50 |

90 |

100 |

| Frame axial stiffness (kN/mm) |

10 |

40 |

60 |

280 |

450 |

700 |

| Power supply |

1 phase, 220V/110V, 50Hz/60Hz |

3 phase, 380V/220V, 50Hz/60Hz |

| Power (kW) |

0.4 |

1/1.5 |

2 |

3 |

4 |

5 |

| Dimension6 (mm) |

385x550x1415 |

780x550x1770 |

1030x660x2390 |

1150x760x2400 |

1210x880x2560 |

| Weight (kg) |

120 |

270 |

330 |

850 |

1600 |

2600 |

| Shipping dimension (mm) |

1600x900x500 |

1930 x 900x700 |

2650x1180x1000 |

2650x1300x1100 |

3150x1500x1250 |

Note:

1. Vertical test space means the distance from bottom surface of moving cross-head to top surface of lower working table, which can be referred when adding other fixtures.

2. Max. Tensile space means the tensile distance when equipped with standard tensile grip.

3. Max. Compression space means compression distance when equipped with standard platens.

4. Single column machine equips with screw action parallel grip for flat specimens.

5. Bending fixture is not included in standard supply, it can be specially offered.

6. Frames with other dimensions (extra height or width) & capacities can be offered upon request.

Appearance and specifications are subject to change without advance notice.