Specifications

|

Model

|

DWC-30

|

DWC-60

|

DWC-80

|

DWC-100

|

|

Temperature range (℃)

|

Room to -30

|

Room to -60

|

Room to -80

|

Room to -100

|

|

Accuracy (℃)

|

≤±0.5

|

|

Effective working space (mm)

|

120×120×80

|

|

Specimen dimension (mm)

|

10×10×55

|

|

Specimen quantity

|

More than 60 pcs

|

|

Cooling media

|

Alcohol or others

|

|

Compressor

|

Fully enclosed type, imported brand

|

|

Power supply (kW)

|

1.0

|

2.5

|

3

|

7

|

|

Dimensions (mm)

|

905×505×910

|

905×505×910

|

905×505×910

|

1260×600×900

|

Notes:

Room temperature down to -150°C /-196°C cooled by liquid nitrogen can be specially ordered according to user’s requirement.

DWCT Temperature Chamber for Impact Specimen in Drop Weight Testing Application

DWCT Low Temperature Chamber for Impact Specimen in Drop Weight Testing is specially designed according to ASTM E 208& equivalent ISO Test Method for DWTT of Ferrite Steel Materials. The Low Temperature Chamber adopts multiple compressors, cooling technology and utilizes the heat balance principle and cycle stirring method to realize the constant cooling to impact specimen. With digital display and automatic control temperature, the Low Temperature Chamber is an ideal equipment for cooling and keeping constant temperature.

Specifications

1.Temperature Range: room to -80°C

2.Temperature Control Accuracy: ± 2°C

3.Temperature Fluctuation: ± 0.5°C

4.Size of Chamber: 600 × 400 × 200mm

5.Specimen Quantity: 18 pcs

6.Cooling Method: multiple compressors for cooling.

7.Cooling Medium: absolute alcohol or others

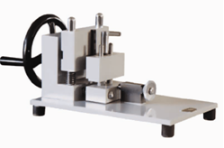

TE-M/UV2 Manual/Hydraulic Notch Cutter for Impact Specimen

Application:

TE-M/UV2 Manual / Hydraulic Notch Cutter for Impact Specimen is specially designed for the preparation of impact specimen. Both manual type and hydraulic type are available for cutting the notch according to the 'V’ ASTM E23, ISO148 standards, 'U’ DIN 50115 and ISO83 standards 'Charpy Notch Impact Test Method for Metal Material’. Meanwhile, the machine also features in high precision, long life, low noise and concise appearance etc.

|

|

Manual Type

|

Hydraulic Type

|

Specifications:

1.Notch Type: V type: 2mm or U type: 2mm

2.Travel of Cutting Knife: 340mm

3.Dim: 400x350x700/600x500x1200mm

4.Size of Specimen: 10 × 10 (7.5 or 5) × 55mm

5.Cutting Speed: 2.5m/min (hydraulic type)

6.Weight: 100/200kg

CTS-50 Projector

Application:

Model CTS-50 is a kind of special projector, which amplifies and projects the U or V-shaped profiles of the measured parts onto the screen to check their profiles and shapes with high accuracy by the optical projection method. The projector is widely used to check the U and V-shaped notch impact specimen. CTS-50 features in easy operation, simple structure, direct inspection and high efficiency.

Specifications:

1.Screen Diameter: 180mm

2.Working Table: square shape 110 × 125mm round shape 90mm

3.Glass Diameter of Working Table: 70mm

4.Working Table Travel (L × W × H):±10 × ±10, ±12mm

5.Rotating Range of Round Working Table: 0 to 360 degree

6.Magnifications: 50X

7.Objective Magnification: 2.5X

8.Projection Objective Magnification: 20X

9.Eye-field Diameter: 3.8mm

10.Working Distance: 22.89mm

11.Light Source: tungsten lamp 12v 100W

12.Dimensions: 515 × 224 × 603mm

13.Weight: 20kg

Non Metallic Specimen Preparation Equipment

CPJ-25 Sheet-punching Machine

This machine is used for machining test samples, such as nonmetallic soft sheets and thin films. Using various kinds of standard cut-off knives, the sheet-punching machine can prepare the required samples accurately and swiftly.

1. Max. Travel: 25mm

2. Max. Thickness of Punching: 2mm

QK-20 Notch Sampling Machine

Specimen prepared by QK-20 Notch Sampling Machine meets the requirements of ISO179, ISO180, GB/T1403, GB/T1483, GB/T8814 on non-metallic specimen preparation;

Dimensions of the cutters:

A: 45°C±1°C R0.25

B: 45°C±1°C R1

C: 2±0.2

ZQK-20 Automatic Notch Sampling Machine

Application:

The automatic notch sampling machine is a special sampling equipment that automatically prepares notch for non-metallic specimen such as plastic, rubber and composite. The automatic notch sampling machine can do impact test by using Charpy and Izod impact testing machine. It is designed according to the standards of ISO179, GB/T1043, GB/T1843 etc. The automatic notch sampling machine features simple structure and convenient operation.

Specification

1.Milling Cutter Length: 60mm

2.Milling Cutter Spindle Rotary Speed: 460rpm

3.Motor Power: 180W

4.Dimensions of the Cutter:

A: 45 °C ± 1 °C R0.25± 0.05

B: 45 °C ± 1 °C R1± 0.05

C: 2 ± 0.2

D: 0.8± 01

5.Outside Dimension: 400 × 350 × 500mm