● One or multi-channel actuators

● Constant servo pump station

● One or multi-channel control system

● Pipes and oil distributors

● Base or table suitable for different samples

Features:

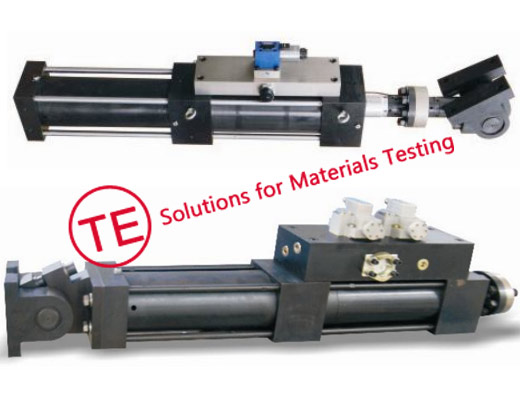

● Module unit design.

● It features low friction, quick response, small exposure inside, and strong anti-lateral load capacity.

● It is equipped with universal joint and suitable for different installation methods (front & back flange, back hinge, foundation installation).

● Double direction piston.

● Sealing method: guide ring + servo sealing ring.

● LVDT displacement sensor is installed inside the actuator while the electro-hydraulic servo valve is installed outside. Teflon guide sleeve is installed between LVDT displacement sensor and piston rod, small friction and good guidance can guarantee the sensor’s trouble-free and long-time work.

● Actuator amplitude limit is designed within hydraulic damping area to avoid running out of control.

● Load sensor is set up on the piston rod end.

Specification:

|

No.

|

Max. Load (kN)

|

Max. Dynamic load (kN)

|

Max. Stroke (mm)

|

Diameter (mm)

|

Max. Speed (mm/s)

|

Working Pressure (MPa)

|

|

15

|

15

|

10

|

±75/±100

|

45/60

|

-

|

21

|

|

30

|

30

|

20

|

±75/±100

|

45

|

1400

|

21

|

|

50

|

50

|

35

|

±75/±125

|

45

|

1400

|

21

|

|

100

|

100

|

70

|

±75/±125

|

70

|

1400

|

21

|

|

150

|

150

|

100

|

±75/±125

|

85

|

1400

|

21

|

|

300

|

300

|

200

|

±75/±125 ±150/±200

|

95

|

1400

|

21

|

|

500

|

500

|

350

|

±125/±150 ±200

|

130

|

1200

|

21

|

|

750

|

750

|

500

|

±125/±150 ±200

|

140

|

-

|

21

|

|

1000

|

1000

|

700

|

±125/±150 ±200

|

150

|

1000

|

21/28

|

|

3000

|

3000

|

2000

|

±125/±150 ±200

|

-

|

800

|

21/28

|

|

5000

|

5000

|

3500

|

-

|

-

|

800

|

21/28

|

|

10000

|

10000

|

7000

|

-

|

-

|

500

|

21/28

|

LVDT, Load Cell and Servo Valve

1. LVDT can be built in the actuator or fixed outside.

2. Load cell is fixed at the end of the actuator, suitable for tensile and compression application.

3. Servo valve can be with two or three grade valve for high response action.

500KN Dynamic Testing System for Building Components

Specification:

● Two actuators

● Max. Static Load: ±500KN

● Max. Dynamic Load: ±350KN

● Stroke of Actuator: ±150mm

● Waveform: sine, triangle, square, oblique

● Frequency: 0.01 to 15Hz

200KN Dynamic Testing System for Hydro-pneumatic Suspension

Specification:

● Two-channel actuators

● Load Capacity: ±200KN

● Stroke of Actuator: ±200mm

● Waveform: sine, triangle, square, oblique

● Frequency: 0.01 to 25Hz

● Max. Velocity: 1.5 m/s

● Servo Valve: 1000L/min three grade valve

● Pump: 740L/min, 28Mpa

● Power: 440KW

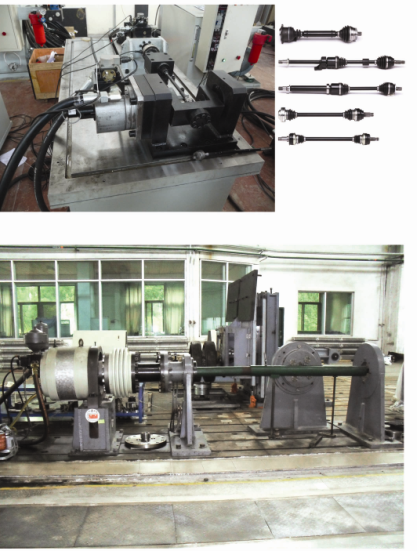

20kN Dynamic fatigue Tester for Vehicle Rack with Two Channels

Specification:

● Actuator: 1 to 4

● Max. Load: ±15KN/±30KN/ ±50KN

● Stroke of Actuator: ±150mm

● Waveform: sine, triangle, square, oblique

● Frequency: 0.01 to 15Hz/0.01 to 50Hz

50KN Dynamic System for Vehicle Stability

Two Actuators

● Max. Load: ±50KN

● Max. Stroke of the Actuator: ±75mm

● Waveform: sine, triangle, square, oblique

● Pump Station: 280L/min

100kN Vibration Table

Specification:

● Max. Push Load: 100KN

● Accelerated Velocity: 0.1g to 5g

● Frequency: 0.01 to 40Hz

Torsion fatigue Tester for axis of vehicle from 10,000Nm to 30,000Nm

Torsion fatigue Tester for transmission shaft 32,000Nm

Test Station for steering unit of vehicles