Applied Standard

1. Load meets or exceeds the following standards: ASTM E4, ISO75000-1, EN 10002-2, BS1610, DIN 51221.

2. Strain measurement meets or exceeds the following standards: ASTM E83, ISO 9513, EN 3846 and EN 10002-4.

3. Safety: This machine shall conform to all relevant European CE Health and Safety Directives EN 50081-1, 580081-1, 73/23/EEC, EN 61010-1

4. Tensile test at room temperature: DIN EN 10002-1, ISO 6892, ASTM A370, ASTM E 8

5. Tensile test on reinforced steel: ISO 10606, EN 10080

6. Compression test: DIN1048, ISO6784, ASTM C39, ISO4506

7. ASTM E143 Test Method for Shear Modulus at Room Temsdperature

8. ASTM F606-07 Tensile test for bolts

9. ASTM A185/A185M-07 Metals & Construction material

Features

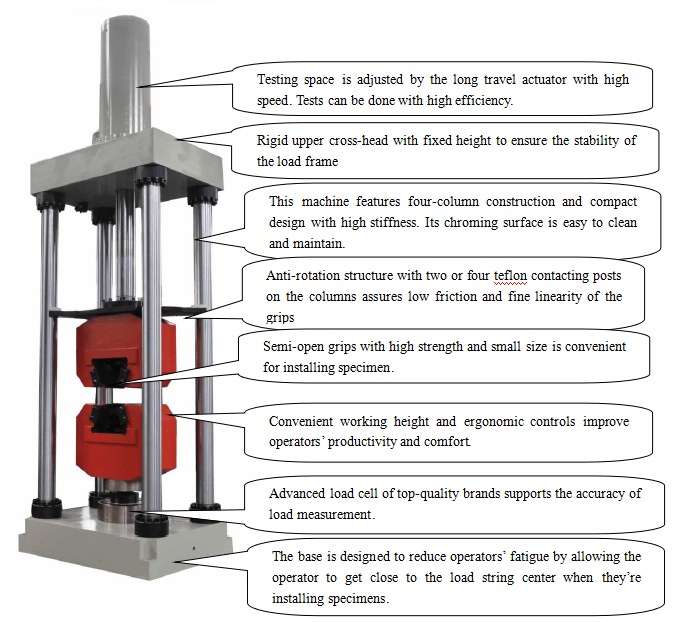

Structure Load frame features

WAW-F series adopts single testing space designed with single central hydraulic drive for loading on specimen directly to do the tests of tensile, compression, bending and shearing etc.. The space created by counter force frame structure is totally eliminated so that the testing results are more accurate and real. The single large test space fully considers operation convenience and safety that raise testing efficiency. Such a large test space also entitles the load frame to adapt a wide range of specimen sizes, grips, accessories, extensometers, furnace, environmental chambers etc.. For the load capacity of 300kN, it has two-column structure, while for the load capacity from 500kN-3000kN, it has four-column structure.

1. Constant pressure and fixed flow rate servo power pack is adopted in the famous and advanced design. The power pack is designed with two constant pressure systems of quick response for loading and clamping.

2. The Servo-Hydraulic Testing System Computerized is capable of low pressure start-up, medium and high pressure switch-over.

3. The oil source consist of fixed oil pump, high and low pressure switch-over module, air cooling device and electric control cabinet.

4. On the front panel, function buttons like main oil pump control, clamping pump control and emergency stop are equipped for easy operation of the computer control electro-hydraulic servo testing system.

5. Intelligent and environmental friendly air cooling device can start and stop at preset temperature.

6. Safety features: oil level protection, oil actuator overflow protection, oil pump over current protection, hydraulic oil overheating protection, overload protection and filter protection.

7. To start and stop the oil pump can be done through software.

8. Two oil filters with high filter grade are installed to ensure the cleanness of the servo system and the actuator’s endurance.

9. Pressure gauges to show the main pressure of the system and the clamping pressure

Specifications

|

Model

|

WAW-300/400F

|

WAW-500F/600F

|

WAW-1000F

|

WAW-1500F/2000F

|

|

Max. Load (kN)

|

300/400

|

500/600

|

1000

|

1500/2000

|

|

Load Measuring Range

|

2 - 100%F.S. (0.2/0.4 - 100%F.S optional)

|

|

Load Accuracy (%)

|

±0.5/±1

|

|

Deformation Measuring Range

|

2 - 100%F.S. (0.2/0.4 - 100%F.S optional)

|

|

Deformation Accuracy (%)

|

±0.5/±1

|

|

Displacement Position (mm)

|

0.001

|

|

Test Loading Speed(mm/min)

|

0.5 - 70 (0.01 - 70 if configured with EDC220 controller & Moog servo valve)

|

|

Max. Crosshead Moving Speed (mm/min)

|

200

|

|

Stress Control Range

|

1 - 60(N/mm2)S - 1

|

|

Strain Control Range

|

0.00025/s - 0.0025/s

|

|

Tensile Space 1 (mm)

|

600

|

600

|

700

|

700

|

|

Compression Space (mm)

|

450

|

450

|

450

|

450

|

|

Piston Stroke (mm)

|

600

|

600

|

600

|

600

|

|

Column Distance (mm)

|

520

|

600 × 350

|

660 × 400

|

800 × 450

|

|

Flat Jaw (mm)

|

0 - 30

|

0 - 30

|

0 - 60

|

0 - 80

|

|

Round Jaw (mm)

|

Φ10 - Φ32

|

13 - Φ40

|

Φ20 - Φ60

|

Φ20 - Φ80

|

|

Jaw (mm)

|

73

|

90

|

110

|

160

|

|

Jaw (mm)

|

73

|

90

|

110

|

140

|

|

Platen Size (mm)

|

Φ150

|

Φ150

|

Φ150/204 × 204

|

Φ200/204 × 204

|

|

Oil Tank Volume (L)

|

ISO VG68# or VG46# hydraulic oil

|

|

60

|

60

|

100

|

200

|

|

Oil Pressure (MPa)

|

26

|

26.5

|

26

|

26

|

|

Weight of Load Frame (kg)

|

2300

|

3000

|

4200

|

8000

|

|

Dimension of Load Frame 3 (mm)

|

880 × 630 × 2980

|

880 × 630 × 2980

|

980 × 720 × 3530

|

1220 × 880 × 4180

|

|

Size of Power Pack (mm)

|

1000 × 680 × 1200

|

|

Shipping Dimension (mm)

|

3000×950×1100 2000×900×1500

|

3000×950×1100 2000×900×1500

|

3500×1100×1200 2000×900×1500

|

4050×1450×1300 2000×900×1500

|

|

Power Supply

|

3PH, 380VAC, 50Hz, 4.1kW

|

3PH, 380VAC, 50Hz, 5.6kW

|

3PH, 380VAC, 50Hz, 8.6kW

|

3PH, 380VAC, 50Hz, 11.5kW

|

*WAW-3000F can be customized upon request.